Glass materials such as borosilicate, aluminum silicate (e.g. Gorilla®), quartz and other types of specialty glass are used in many applications due to their unique properties such as thermal and dimensional stability, surface quality, hermeticity, process compatibility and optical performance and as flat and hollow glasses in many industries.

In order to process the glass materials, many manufacturers now use laser technology. Laser processing of glass enables rapid, highly precise and highly reproducible processing of brittle glass substrates. Compared to conventional processing methods, laser processing scores with:

- Free-form geometries

- Internal contours

- Best surfaces- and edge quality

- Minimal chipping

- Possibility for processing coated substrates

- No masks, wear parts and other expedients necessary

The processes range from laser cutting through the production of filaments/modifications, laser drilling up to layer-by-layer ablation to the manufacturing of 3D structures. In addition, the laser is ideally suited for removing coatings thanks to its high selectivity. Furthermore, laser engravings can be generated on the surface or inside the material.

The processing of the glass materials takes mostly place in the form of round substrates such as wafers all the way to large-area panels. Increasing the production throughput requires the processing of ever larger panels or even the conversion of wafer processing to panel processing.

Typically, in industrial applications, rigid glasses with a thickness of greater than 0.3 mm are used. Currently, the latest developments are being pushed towards thinner and more flexible substrates. This trend offers the opportunity for new applications and designs. For manufacturers, this means above all the conversion to new and flexible production technologies.

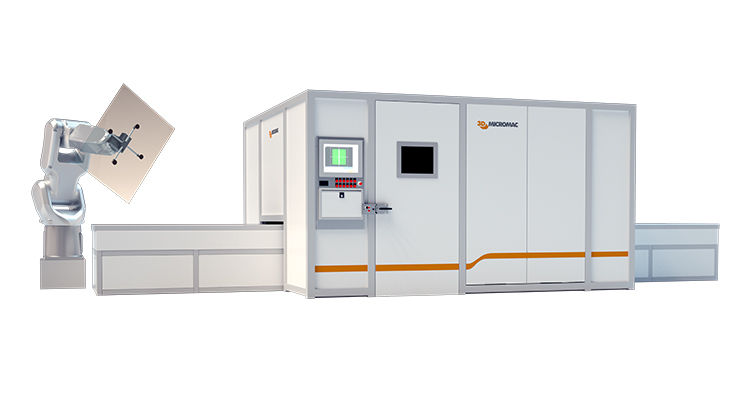

With the microSHAPE laser systems, 3D-Micromac offers unique processing technologies and innovative process management for the cost-effective and high-quality processing of wafers and large glass substrates. All processes meet the requirements of industrial customers and guarantee clean and gentle processing as well as excellent processing quality.